Fully automatic circuit board dismantling machine is used to remove electronic components from waste circuit boards. Because different components contain different metals, some components contain precious metals such as gold and silver, while others contain toxic substances. Some components can be directly sorted and sold. Dismantling the boards makes it easier to crush and separate the copper, thus greatly reducing the workload of the crushing and sorting sections, and increasing the recycling rate of precious metals.

- Product Details

- Feature

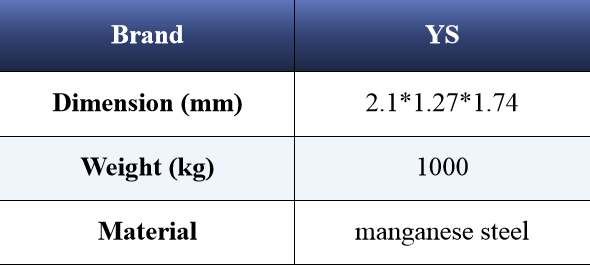

- Parameter

- Application

- Inquiry

- Fully automatic control, saving manpower, typically requiring two operators per shift.

- Automatic temperature control with heating system, no manual intervention required.

- High output, with a capacity of 200 to 500 kilograms per hour.

- Simple operation and reliable safety of the fully automatic circuit board dismantling machine.

- After separation, each component enters its respective next stage process, enhancing economic efficiency.

- Reduced damage to components, with minimal loss of precious metals.

- Equipped with smoke treatment facilities, environmentally non-polluting.

This machine features automation, high processing efficiency, low operating costs, small footprint, easy operation, and absolutely no dust pollution. The processed boards can be recycled for copper and other metals through physical methods, while electronic components can be environmentally classified for safe recycling and reuse.

Prev: Copper Granulator

electric waste recycling solutions supplier

electric waste recycling solutions supplier